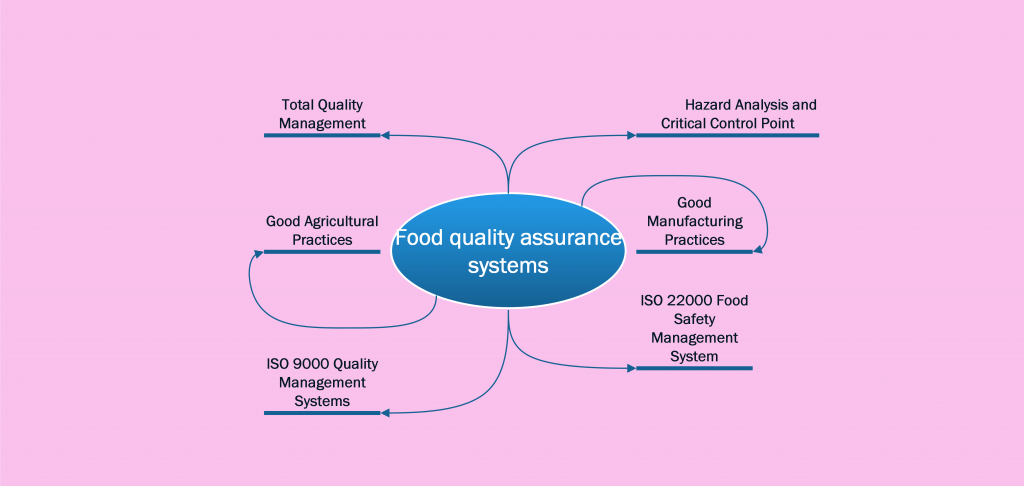

A number of quality assurance (QA) systems are available to the food industry such as

- GMP (Good Manufacturing Practices),

- HACCP (Hazard Analysis and Critical Control Points), and

- ISO (International Organization for Standardization) standards such as ISO 9000 (Quality Management System) or ISO 22000:2005 (Food safety management systems – Requirements for any organization in the food chain).

For food quality and health control these programs and their combinations are recommended. The production of agri-food requires a particular approach for achieving the desired level of quality. It is crucial to know how much the programs relate to the overall product output and to align the resources used to achieve the quality and safety goals [12].

A quality management system (QMS) system can be defined as: a set of coordinated activities to direct and control an organization in order to continually improve the effectiveness and efficiency of its performance [12].

According to Rotaru and others [12], the QMS can be categorized according to the extent of activities they cover:

- basic safety systems: prerequisites (GAPs, GMPs, GLPs, etc.);

- advanced safety systems such as HACCP;

- integrated food safety management – ISO 22000;

- basic quality management systems – ISO 9001;

- advanced quality management systems – ISO 9004

Prerequisite programs

These are programs that are required as a prior condition for other systems to exist and work effectively. A good example is the Good Manufacturing Practices (GMPs) which are the minimum sanitary and hygiene requirements for food producers. GMP recommendations are not formalized directives on how to manufacture goods. These are a set of general concepts to be followed during food production. See further discussion of Good Manufacturing Practices (GMPs), Good Agricultural Practices (GAPs) among others.

Hazard Analysis and Critical Control Points (HACCP)

HACCP is a systematic preventive, and proactive approach to food safety, focused on the identification and control of all biological, chemical and physical hazards from the processing of raw materials through the manufacture, distribution and consumption of the final product [12, 13]. The system is based upon seven principles:

- Principle 1: Conduct a Hazard Analysis

- Principle 2: Identify the Critical Control Points

- Principle 3: Establish Critical Limits

- Principle 4: Establish Monitoring Procedures for critical control limits

- Principle 5: Establish Corrective action procedures

- Principle 6: Verification of HACCP programme

- Principle 7: Effective record keeping and documentation

Basically, HACCP systems are designed to:

- Prevent hazards from occurring

- Eliminate any existing hazards completely

- Reduce any existing hazards to levels that are harmless to consumers making the food safe.

ISO 9001 Quality management systems — Requirements

The ISO 9001 belongs to a family of standards: ISO 9000 family of standards that are designed to assist organizations of all types and sizes, to implement and operate an effective quality management system.

- ISO 9000 describes fundamentals of quality management systems and specifies the terminology for quality management systems.

- ISO 9001 specifies requirements for a quality management system where an organization needs to demonstrate its ability to provide products that fulfil customer and applicable regulatory requirements and aims to enhance customer satisfaction.

- ISO 9004 provides guidelines that consider both the effectiveness and efficiency of the quality management system. The aim of this standard is improvement of the performance of the organization and satisfaction of customers and other interested parties.

- ISO 19011 provides guidance on auditing quality and environmental management systems.

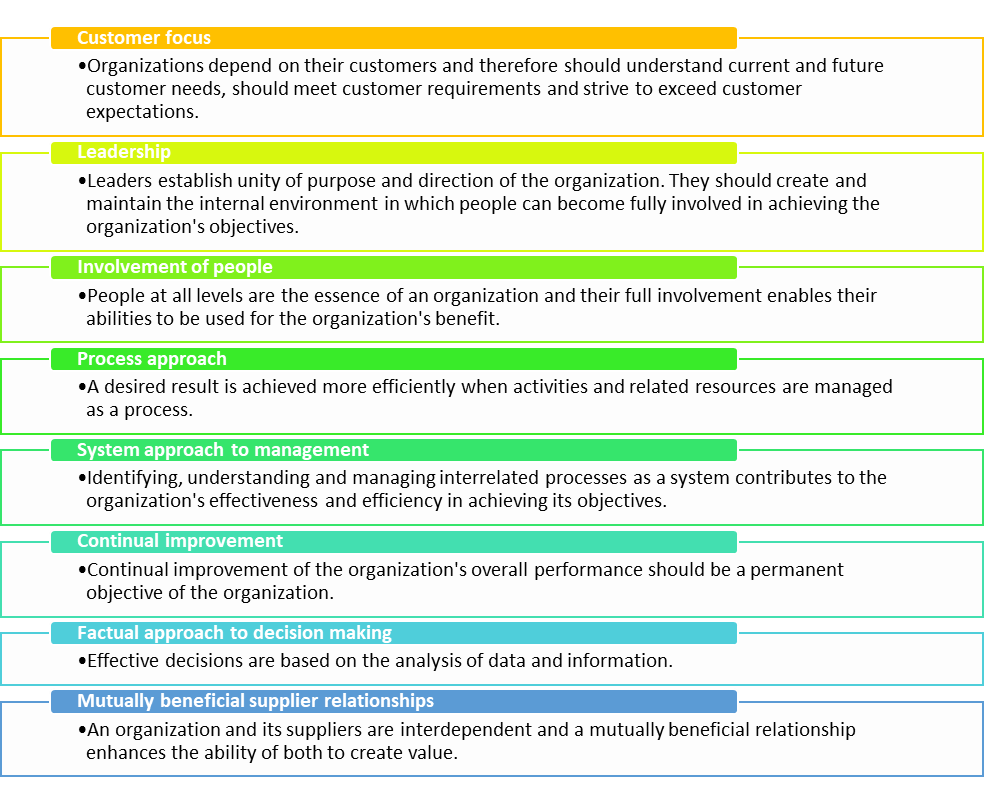

Eight concepts of quality management have been established which can be used by the top management to guide the company towards better results as shown in the figure below.

Read more about ISO 9000 standard here!

ISO 22000, Food safety management systems

ISO 22000, Food safety management systems – Requirements for any organization in the food chain, was first published in 2005. The standard provides international harmonization in the field of food safety standards, offering a tool to implement HACCP (Hazard Analysis and Critical Control Point) throughout the food supply chain.

The goal of ISO 22000 is to control, and reduce to an acceptable level, any safety hazards identified for the end products (An end product is defined as a product that will not undergo any further processing or transformation by the organization) delivered to the next step of the food chain.

Some highlights of ISO 22000 include:

- The establishment of prerequisite programs (PRPs),

- The identification and control of food safety hazards, and the determination of an acceptable level of risk

- The establishment of a HACCP plan

- The control of nonconformity in food products

- The establishment of a food safety team

- The establishment of a communications plan with external parties

- The establishment of a traceability system

Read more here: ISO 22000:2005 and ISO 22000: 2018

Some key advantages of implementing these systems include:

- recognition by international community

- marketing edge

- costs reductions

- Improved efficiency in processing

- Improved customer relations

Companies seeking to implement these systems should learn from others on difficulties that they would expect to encounter [14, 15]. It is however important to note that these systems are company or factory specific.