What is the meaning of traceability in food?

Traceability is usually the ability to identify the origin of a food, an entity or a food source along the food chain. This includes an entity’s history, activity, or position along the value chain.

It is also known as the ‘one-step-back-one-step-forward’ principle. This is an important principle especially when the food products are found to be faulty [34].

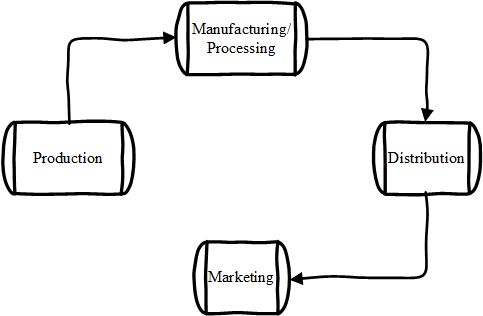

Where food products are considered, this is the ability to follow the movement of a food product through the specific stages of production, processing, and distribution, including food-producing animals (Figure 1).

According to the International Organization for Standardization (ISO), traceability is the “ability to follow the movement of a feed or food through specified stage(s) of production, processing and distribution” [34, 35].

Codex Alimentarius Commission (CAC) also defines traceability as “the ability to follow the movement of a food through specified stage(s) of production, processing and distribution” [34].

Importance of a food traceability system

Food traceability systems are important because of a number of reasons [34, 36-41]:

- There has been many outbreaks of disease linked to animals that could be transmitted to humans such as the avian flu

- There has been many incidences of pathogenic microorganisms occurring in food and food products

- There are many reports indicating the presence of toxic chemicals above acceptable limits in food and food products

All these incidences have potential to cause public health issues including foodborne diseases. The occurrence of food safety hazards along any food chain must be eliminated. However, in the event that they occur, it is highly important that there be an established system to prevent the occurrence of foodborne diseases. Key among these systems is a system for recalling or withdrawing faulty and unsafe foods from the market. Another important aspect is the identification of the source of the problem and eliminating it to prevent future occurrences. To achieve this, a traceability system is required. This is because:

- It is important that when authorities or food companies detect a risk they can trace it back to the source to isolate the issue quickly and avoid unsafe goods from reaching customers.

“Product Recall is defined as the action to remove food from the market at any stage of the food chain, including that possessed by consumers.

FAO (2017)“

- The food chain is increasingly becoming complex and global involving large number of players. Simple mistakes in the food chain have the potential to reach pandemic proportions

- Failure to recall products will result in continued exposure to toxic products which is injurious to public health. There is a major risk of an epidemic or a pandemic occurring

- Unless the origin or the source of the faulty products along the food chain is identified, unsafe end products may continue to be produced. In this case, the manufacturers may be forced to close production lines for a long time until the sources are found and exterminated. This is bad for business and the economy since jobs and income may be lost.

- Traceability systems emphasize on prevention rather than reacting to eventualities which has potential to protect public health

- With traceability systems in place, it is easy to provide accurate information to avoid confusion in the public in the case of a recall

- Properly implemented traceability systems would lead to a more informed management in decision making. Coupled with visibility created may lead to reduced production costs and better market penetration.

- Traceability systems provide consumers with confidence in food products since they know that the manufacturer has taken the initiative to preserve public health.

Principles and requirements for the design and implementation of a food traceability system

International Organization for Standardization (ISO) developed a standard addressing traceability in the feed and food chains labeled as ISO 22005:2007 – Traceability in the feed and food chain — General principles and basic requirements for system design and implementation.

This standard is designed for any organization in the feed and food chains that wants to design and implement a traceability system.

ISO 22005:2007 standard allows organizations operating in the food chain to [34]:

- Trace the flow of all materials whether food, ingredients or packaging materials that are required at any stage or step in the food chain

- Identify the necessary documentation or records and tracking at each production stage

- Ensure that there is adequate coordination between all the actors involved in the food chain

- Improve and ensure effective communication among the actors

- Ensure that the information is reliable and is appropriately used as well as the effectiveness and productivity of the organization

Characteristics of traceability systems

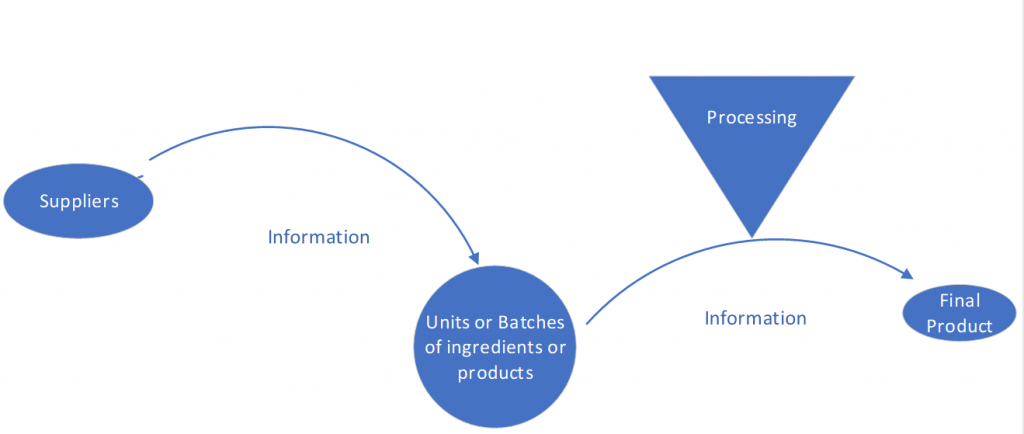

As mentioned earlier, traceability is usually the ability to identify the origin of a food, an entity or a food source along the food chain. This includes an entity’s history or records, activity, or position along the value chain. It includes the trail of materials as they come from various sources until a final end product is obtained. This does not stop as the food is followed up until it lands on the consumers table.

“A good traceability system should be able to recall food products that are stored in the consumers freezer back to the manufacturers. It should in fact be able to identify the sources and quality attributes for all ingredients used for any given packet of food at the consumers table.”

The basic characteristics of any traceability system include:

- The identification of all ingredients and products units or batches;

- The registration of information concerning the movement or transformation of the units or batches

- A system linking the information concerning the units or batches and transferring all the relevant traceability information with the products to the next processing step along the food chain.

“There must be a link between the flow of products and the flow of information.”

Types of traceability

There are two types [34]:

- External traceability – According to Diallo, Henry [42], internal traceability concerns private information such as data on product design and manufacturing parameters, raw material origin, and quality records

- Internal traceability – According to Diallo, Henry [42], external traceability is considered as public data which is exchanged between the various partners in a supply chain to ensure end-to – end traceability.

Data types, data collection methods, and storage for the two traceability types are different. Both levels of traceability make the recall process useful. To determine the root causes for noncompliance, the internal traceability data is mostly required. The external traceability is necessary to determine the location of the items to be recalled, the supplier of a given raw material and the management of a noncompliant product.

“External traceability is used to assess the position of items to be recalled, and to coordinate measures for recall. Internal traceability leads to the root cause analysis in order to identify the causes of non-compliance and to a targeted recall

ITC [34]”

Requirements for a good traceability system

A good traceability system must be:

- Accurate

- Scalable

- Dynamic

- Cost-effective