Van Doremalen, Bushmaker [16], assessed the survival of the COVID-19 virus on different surfaces and indicated that the virus could remain viable on plastic and stainless steel for up to 72 hours, on copper for up to four hours and on cardboard for up to 24 hours. This has caused alarm on may people with questions lingering on their minds regarding the ways through which the virus may be transmitted. Key among those questions is whether COVID-19 may be transmitted through food?’ and Is food safety a problem amidst COVID-19?

Currently, it is known that COVID-19 is transmitted through a number of ways [17]:

- Close contact through respiratory droplets (formed on coughing or sneezing) and by fomites (objects or materials which are likely to carry infection, such as clothes, utensils, and furniture).

- Person-to-person contact when a COVID-19 case coughs or sneezes, producing droplets that reach the nose, mouth, or eyes of another person.

- Contact with objects and surfaces surrounding the infected persons where the respiratory droplets may have landed since they are too heavy to be airborne

Can COVID-19 be spread through food or water?

For anything to be a vector of a disease-causing agent, it must be able to sustain the agent and keep it viable until it infects the next person. Viruses require a living host to survive and thus, it may not be transmitted through food. According to the WHO [17], to date, there is no scientific proof of viruses which cause respiratory diseases to be transmitted through either food or food packaging. However, considering that the virus may survive for some time in the environment, food may be a source if it is contaminated with the virus.

According to the Center for Disease Control and Prevention (CDC) [18], an individual may get COVID-19 by touching a surface or object, including food or food packaging, which has the virus on it and then touching his or her own mouth , nose, or probably eyes. However, this is not thought to be the principal way the virus spreads. There is currently no data to indicate that COVID-19 is associated with processing food or eating food. Furthermore, the virus causing COVID-19 has not been reported in drinking water.

“This simply means that the chance of getting COVID-19 through food or drinking water is very low. Unless the food is handled by an infected person shortly before you consume it!”

What can the food industry do to prevent spread of COVID-19?

There are food quality assurance systems that have been in existent in the food industry for ensuring the quality and safety of food products. These systems are voluntary and many manufacturers have taken the initiative to implement them to ensure food safety.

Prerequisite programmes such as good manufacturing practices (GMPs) must be implemented. This is because they have potential to ensure the hygiene and sanitation in the plant as well as personal hygiene. The GMPs are normally part of most quality assurance systems.

Most food manufacturers have implemented some quality assurance systems including HACCP (Hazard Analysis and Critical Control Points), and ISO (International Organization for Standardization) standards such as ISO 9000 (Quality Management System) or ISO 22000:2005 (Food safety management systems – Requirements for any organization in the food chain). These are guidelines that not only seek to ensure basic hygiene practices in the factory but also ensure that hazards (biological, chemical or physical) are eliminated from the food chain and the end product.

Read more about HACCP and ISO standards here: An overview of food quality assurance (QA) systems

Following the guidelines stipulated in these systems coupled with further guidelines from the WHO, may be sufficient to ensure that not only COVID-19 but also other communicable diseases do not find their way within the factory population:

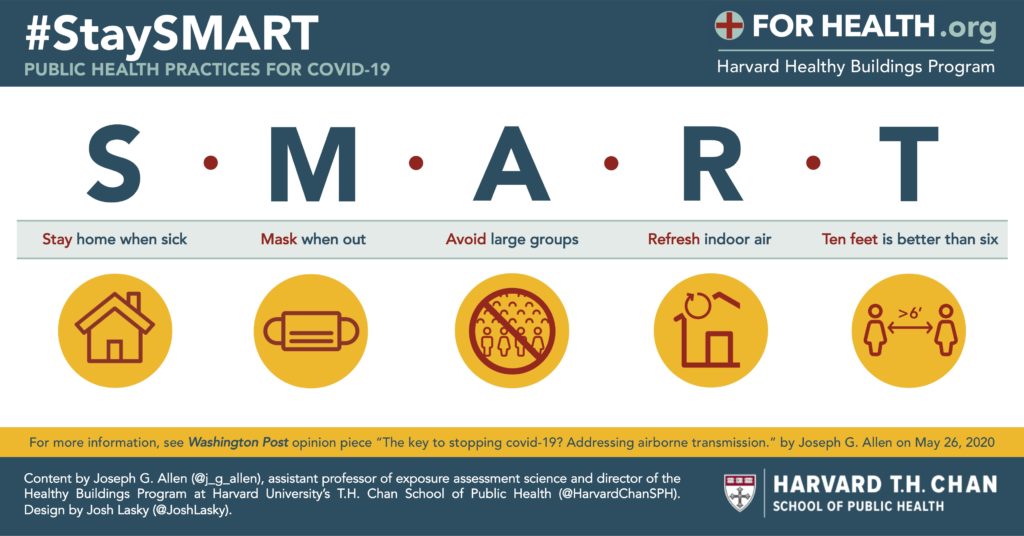

For instance, GMPs are directed towards preventing food contamination as well as cross contamination. They are a baseline, minimum requirement, for there to be safe food. They are a requirement, or prerequisite for other safety systems such as the Hazard Analysis and Critical Control Point (HACCP) system [7]. GMPs require that workers should maintain their personal hygiene. Working surfaces should be kept clean, meaning they should be regularly cleaned. Washing hands must be done regularly and especially when an operator touches other objects or walks out of the factory floor and back. Food handlers should wear masks and avoid touching their faces while handling food as contaminants may enter the food or the other way round in the event that they were handling non food toxic substances.

It is also a requirement that operators who are sick should not be allowed into the food processing environment. They should stay away until they are well and cleared by a medical officer to resume duties. In fact, all operators must have a food handlers medical clearance certificate that is renewed regularly showing that the person has no communicable diseases.

These are the same guidelines that are being advocated for in the fight against COVID-19. However, some stipulations such as the requirement for food handler’s medical clearance certificate which lasts 3 or 6 months for some manufacturers may not work for COVID-19 case. Changes should be done to allow for regular checks for individual body temperature, preferably on a daily basis to identify any person who was probably exposed.

Therefore, any manufacturer in the food chain must endeavor to implement any quality assurance system to eliminate all physical, chemical and biological hazards from the food and top it up with key guidelines that are specific for the COVID-19 case.

In relation to COVID-19, clearly, it is the people working in the factory floor who are at risk. The guidelines drafted by WHO should be sufficient to ensure safety of the workers.

The food industry should endeavor to ensure food safety amidst COVID-19.

To ensure that we cub the spread of this virus the food industry should:

- Endeavour to get the most reliable information from reliable sources such as the WHO. Many myths have been concocted that have potential to mislead with dire consequences.

Get reliable information here!

- Enhancing operator’s awareness of COVID-19 symptoms and encouraging them to communicate immediately when they suspect that they could be infected. It’s important that reporting systems are established so that when they suspect they could have been infected they can use communication systems that do not require physical contact such as email.

- A policy should be formulated for the workers to feel free to report any ailments. Workers who may think that they may lose their job may hind their ailments with devastating results!

- Common symptoms of COVID-19 may include [17]:

- a fever (high temperature – 37.5 degrees Celsius or above).a cough – this can be any kind of cough, not just dry

- shortness of breath

- breathing difficulties

- fatigue

- Training should be organized to help the operators know how they can best prevent COVID-19. If possible, written instructions should be attached on all working areas.

- Normal routine fitness to work procedures, employed by food businesses as part of their FSMS should ensure that infected workers are excluded from food premises. Changes can be made to ensure that the health of the workers is examined on a daily basis, probably every morning before work commences.

- Social distancing, not only when they leave the factory grounds but especially when they are working. In places where workers originally would face each other, such arrangements have to be changed. Although spacing workers may reduce the speed of work, in the long run, it will be the best decision as it will ensure that processing is only slowed down, not stopped.

- Personal protective equipment must be worn at all times and by all personnel in the factory. This is because despite the checks, not all COVID-19 cases are symptomatic. Apparently healthy individuals may carry and spread the virus.

- Maintaining personal hygiene should be taken as a requirement for any worker considering the asymptomatic case that may spread the virus without showing any symptoms. The factory must ensure that workers have access to washing areas and should provide soap and hand sanitizers whenever necessary.

- Maintaining the hygiene of the working environment. The working surfaces must be regularly cleaned and disinfected. This includes any surfaces or objects that are regularly touched such as door knobs, support rails along stairs etc

- Disposable gloves are not ideal in the food environment. When the reusable gloves are used, they must be washed before use and immediately after use or when they touch non food items. Key to note is that they should not be used as an alternative to washing hands since they will serve to transfer the virus between surfaces and objects including the food.

Note: Handwashing is a greater protective barrier to infection than wearing disposable gloves.

- If an employee is confirmed to have COVID-19 contact tracing is necessary to notify all close contacts of the infected employee so they too can take measures to minimize further risk of spread. The factory may notify health officials for purposes of quarantine. If it is suspected that the entire factory staff may have been exposed, the factory may become a quarantine facility or rather all staff should undergo mandatory quarantine.

- During transportation of food from the manufacturer to the retailers, transmission of the virus may occur if the transporter who is infected handles the food products which the retailer in turn handles and subsequently touches their eyes, or mouth without washing their hands. Thus, transporters must be monitored similarly to the factory personnel and trained likewise.

- Factories that use reusable containers must implement systems to ensure transmission does not occur when the containers are returned. Switching to disposable containers may be the better option.

- Factories that offer retail services should monitor consumers and ensure that they adhere to social distancing, hand washing and wearing of masks while purchasing food stuff. The sale of unwrapped food stuff should be abolished. Notices should be pined around the premises for workers and buyers to adhere to stipulations and the frequent cleaning of surfaces should be done for frequently touched objects and surfaces.

- Any factory must be able to verify that their guidelines are being followed….. VERIFICATION is the most important aspect of ant FSMS as it is the basis for CONTINOUS IMPROVEMENT.

- Every factory should endeavor to make these guidelines as part of their standard operating procedures (SOPs).